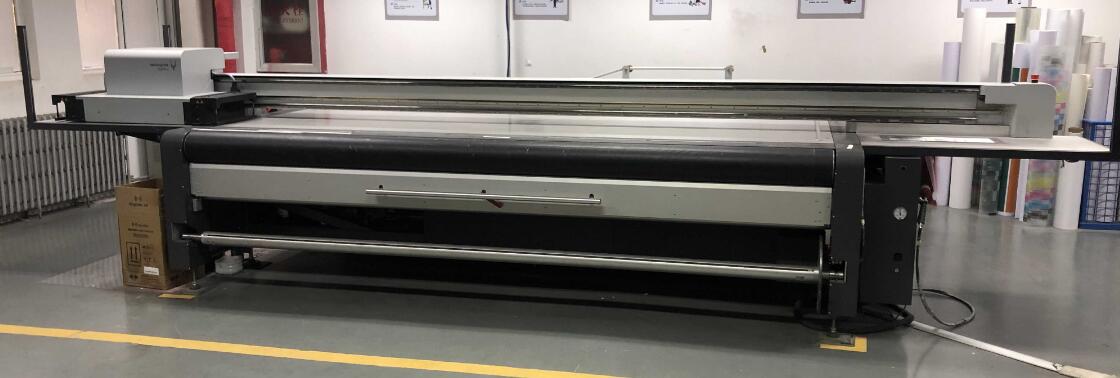

VUTEK GS3250lx Pro with UltraDrop Fine Drop Gray Scale Printing Technology is a highly versatile, cost-effective, efficient, and environmentally friendly printer among its counterparts.

Eight colors with the option of dual-channel configuration: Configurations with single or dual-channel white ink offer many profitable applications, and configurations with single-color transparent ink expand the range of applications.

Switchable to Fast-4 mode for increased production efficiency.

True 600 dpi or 1000 dpi resolution.

Innovative LED technology supporting a wide range of printable materials.

UltraDrop Technology with 7pL fine drop gray scale printing.

Orion operating system.

Fast-4: Produces 223 square meters per hour or 60 sheets of 1.2m x 2.4m boards per hour.

Eight-color printing with white ink: Produces 111 square meters per hour or 32 sheets of 1.2m x 2.4m boards per hour, with efficient continuous production capability and short job changeover cycles (less than five seconds between two board jobs).

Multi-layer printing in a single pass.

Standard multi-queue on-demand printing feature.

Precise alignment lines for accurate image alignment.

Fiery® proServer provides Fiery XF digital front end (DFE) and color management workflow.

Bi-directional communication between Fiery XF digital front end and printer.

Seamless integration with EFI web-to-print and MIS/ERP system solutions through connection with local JDF.

Your printer, Fiery proServer hardware, and Fiery XF software are covered by Enhanced Service Program (ESP) warranty.

This high-performance LED flatbed and roll-to-roll hybrid printer, equipped with innovative LED cold-curing technology and 7pL fine drop gray scale printing UltraDrop technology, enhances image quality and expands the range of printable materials. The compact design of LED curing technology helps improve efficiency and save costs. By providing better quality business while reducing costs and increasing revenue in a more environmentally friendly manner:

Expand the range of printable materials, including low-cost and high-value professional media.

Instant on/off function and less maintenance increase uptime and productivity.

Research conducted by Fogra* shows up to 82% reduction in energy consumption and fewer consumables, resulting in lower operating costs.

Consistent color output and simplified operation reduce waste.

Meeting customer demand for environmentally friendly printing solutions by reducing volatile organic compounds, energy consumption, waste, and consumables.

Demanding users seek the best quality, excellent results, and maximum output. EFI's UltraDrop fine drop technology offers smaller drop diameters and more precise control, which is an incredible technological innovation:

7pL print heads with accurate multi-drop positioning at each dot location.

Four-level gray scale and two sets of ink densities achieve high-definition and high-resolution image quality.

Excellent smoothness in shadow areas, gradient areas, and transition areas.

Outstanding text quality in standard four-pound text mode with minimal satellite phenomenon commonly found in printed materials, resulting in higher clarity.

Please note that the translation is provided based on the information provided. It is always recommended to refer to official documentation or contact the manufacturer for accurate and up-to-date information.

The versatile EFI™ VUTEk® GS5000r helps you achieve high-profit POP image quality jobs and long-term commercial outdoor graphics with billboard productivity.

Technical Features:

8-color high-definition printing with 4 light colors

720 dpi clarity resolution (360 dpi addressable)

Newly added precise double-sided printing function, enabling printing on both sides of the material

Color conversion between 4-color and 8-color completed within one minute

Switchable between solvent-based ink and dye-sublimation ink

Printing output of up to 1,076 square feet per hour (100m2/hour)

Industrial production design, capable of working continuously 24/7

Printing Media: Vinyl, pressure-sensitive, paper, mesh fabric rolls

Specifications: Maximum roll width of 126" (320 cm), maximum print width of 125" (318 cm)

Printing Technology: 24X7 technical support

Supported File Formats: All desktop system file formats, including PostScript?3TM, EPS, TIFF, PDF, RGB/CMYK.

Operating Environment:

Compressed Air: 80 pounds per square foot, dry air.

Temperature: 20°C to 29°C (68°F to 85°F)

Humidity: 20% to 80% (non-condensing)

Please note that the above translation is provided based on the information given. It's always recommended to refer to official documentation or contact the manufacturer for accurate and up-to-date information.

SwissQ

SwissQ is a brand of printers known for their high-quality and precision printing solutions. SwissQ printers are often used in professional printing applications, such as large format printing, signage, graphics, and packaging. These printers are designed to deliver exceptional print quality, color accuracy, and durability.

SwissQ printers are known for their advanced features and technologies that enable efficient and reliable printing. They often incorporate innovative print heads, ink systems, and software solutions to optimize performance and productivity. The printers are designed to handle various print materials, including paper, vinyl, fabric, and rigid substrates.

SwisDurst P10 320R

UV Roll-to-Roll Printer

The fastest 10PL UV roll-to-roll printer in its class

The Rho 320 UV roll-to-roll printer sets new quality standards for industrial roll-to-roll printing. It features high-precision components from Durst, including the Quadro 10 matrix print head technology and magnetic suspension transfer system. Its exquisite quality is suitable for printing high-definition images and backlit displays, as well as direct applications on textiles and flexible media. It can simultaneously print two rolls of media, each up to 1.6 meters wide, side by side, and supports unattended printing.

Key Features of Rho P10 320R:

The latest Durst Quadro 10 matrix print head technology ensures excellent print quality and speed.

It offers cost-effective high-pigment inks, reducing ink consumption.

Simple and fast media replacement minimizes consumable waste.

Built-in safety system (GSM sends error alerts via mobile phone), designed for unattended operation.

Intuitive operating software for easy and user-friendly operation.

Highly productive workflow that can interpret, transfer, and print files through third-party RIP workstations.

Please note that the information provided is a translation and may not reflect the exact marketing or technical terminology used by the manufacturer.

JHF R6000

Ability to easily print large-format images with a width of 5000mm and unlimited length.

◆ Utilizes 360dpi physical precision and high-speed industrial-grade print heads to achieve 1000dpi print accuracy, resulting in superior image quality.

◆ Equipped with high-precision and silent linear guides for a quiet printing process.

◆ Features four large-diameter rubber rollers to reduce deflection, ensuring smooth material movement and providing protection for printed images. Ideal for high-volume, high-speed printing.

◆ Utilizes high-precision metal grating rulers and imported high-performance servo motors, employing closed-loop high-precision control technology for unparalleled print accuracy.

◆ High-precision electric vacuum system reduces compressed air consumption by over 90%, effectively improving the lifespan of the air compressor.

◆ Incorporates industrial-grade PLC control module for stable control of every aspect of the machine.

◆ Equipped with a high-precision automatic head lifting and height measurement system to ensure consistent print quality for each print.

◆ Utilizes top-level cable chain solution, saying goodbye to cable failures during movement.

◆ Employs world-class UV lamp curing solution for perfect image curing.

◆ Unique dual-level ink cartridge control technology ensures ink safety without leakage during sudden power outages.

◆ Rectangular triangular welded frame ensures high strength and no deformation of the machine.

◆ Features a tension feeding system with a national patent, combined with large-diameter rubber rollers, ensuring precise feeding at every step.

◆ National patent-awarded pressure roller structure provides a solid foundation for smooth material feeding.

◆ Impressive appearance with a national design patent, giving you a sense of solidity and reliability.

R6000 Specifications:

Maximum print width: 5000mm

Printing modes:

Production mode: 720×720dpi, 130/110 m2/h

Fine mode: 720×1080dpi, 90/80 m2/h

Ultra-fine mode: 720×1440dpi, 75/60 m2/h

Materials: PVC light cloth, PET sheets, various car stickers, textile fabrics, and other roll-to-roll materials

Ink colors: CMYK, Lc, Lm

GZH5006SG

The main wall panel is made of 20mm thick cast iron, and the main crossbeam is positioned with dowel pins to ensure structural strength and integrity of the machine body. The carriage movement uses a 750W AC servo motor and reducer to guarantee stability for continuous operation. It adopts the latest pressure roller technology from GONGZHENG, with automatic adjustment of contact points based on material thickness. It features an industrial-grade vacuum system that ensures uninterrupted printing, as well as a durable industrial-grade linear encoder for high stability. The mobile material feeding and fixing frame is suitable for printing different width materials, ensuring smooth material feeding.

The main wall panel is made of 20mm thick cast iron, and the main crossbeam is positioned with dowel pins to ensure structural strength and integrity of the machine body. The carriage movement uses a 750W AC servo motor and reducer to guarantee stability for continuous operation. It adopts the latest pressure roller technology from GONGZHENG, with automatic adjustment of contact points based on material thickness. It features an industrial-grade vacuum system that ensures uninterrupted printing, as well as a durable industrial-grade linear encoder for high stability. The mobile material feeding and fixing frame is suitable for printing different width materials, ensuring smooth material feeding.

Model: GZH5006SG

Type: Solvent series

Printhead Technology: SG1024 (25PL/10PL)

Printhead Control: Software automatically adjusts printhead temperature and voltage

Ink Tank: Solvent ink with a capacity of 5000ml

Material Handling: Roll-to-roll

Ink Characteristics: Solvent-based ink

Drying System: Wide-width internal and external intelligent drying fans (segmented heating at 1.7m/3.4m/5m respectively)

RIP Software: Photoprint

Color Control: Compliant with international standards, with curve and density adjustment functions

Image Formats: TIFF, JPEG, Postscript, EPS, and PDF

Power Requirements: Machine: 10A/220V, Drying Fan: 16A/380V

Operating Environment: Optimal temperature: 20°C-28°C

Relative Humidity: 40%-70%

Printing Size: 5m

Media Thickness: 2mm

Number of Printheads: 2/4/6 optional

Printing Accuracy: 300dpi×400dpi, 300dpi×600dpi, 300dpi×800dpi

Printing Speed: 2pass 300x400dpi: 450㎡/h, 3pass 300x600dpi: 300㎡/h, 4pass 300x800dpi: 240㎡/h

Colors: CMYK four colors

Supported Materials: Printing cloth, lightbox cloth, wallpaper, leather, mesh fabric, car stickers, etc.

HT3200UV-K10-H

The HT3200 roll-to-roll UV digital printer is a cost-effective UV flatbed printer designed specifically for small and medium-sized processing enterprises. Equipped with a high-performance piezoelectric printhead combination, it can achieve high-speed printing at a maximum resolution of 1200x1200dpi and a speed of 23 m²/h, achieving the best balance between speed and quality. The HT3200 roll-to-roll UV digital printer adopts a dual screw motion control system to ensure perfect positioning for both rigid and flexible materials, with a repeat positioning accuracy of 0.05mm. It is designed for 24/7 industrial production mode. The vacuum absorption platform securely holds materials up to 2mm thick on the work platform. The advanced pressure roller stepping system ensures accurate stepping, and the leading high-energy LED curing system is suitable for thin and heat-sensitive materials. The platform water cooling system allows temperature control and adjustment for different materials. The operation is simple and easy to understand, and the various white ink modes provide the printer with greater versatility.

The HT3200 roll-to-roll UV digital printer is a cost-effective UV flatbed printer designed specifically for small and medium-sized processing enterprises. Equipped with a high-performance piezoelectric printhead combination, it can achieve high-speed printing at a maximum resolution of 1200x1200dpi and a speed of 23 m²/h, achieving the best balance between speed and quality. The HT3200 roll-to-roll UV digital printer adopts a dual screw motion control system to ensure perfect positioning for both rigid and flexible materials, with a repeat positioning accuracy of 0.05mm. It is designed for 24/7 industrial production mode. The vacuum absorption platform securely holds materials up to 2mm thick on the work platform. The advanced pressure roller stepping system ensures accurate stepping, and the leading high-energy LED curing system is suitable for thin and heat-sensitive materials. The platform water cooling system allows temperature control and adjustment for different materials. The operation is simple and easy to understand, and the various white ink modes provide the printer with greater versatility.

The HT3200UV_A_RK4 Kyocera digital printer can directly print on various flexible materials. It is suitable not only for advertising products such as lightbox films, car stickers, knife-coated fabrics, translucent films, and soft membranes but also for artistic and personalized product processing, such as glass film, leather, wallpaper, and other flat materials.

It has complete independent research and development capabilities to ensure continuous functional upgrades of the machine. The leading high-energy LED curing system with low-temperature LED light source is suitable for thin and heat-sensitive materials. The unique platform water cooling system ensures that printing materials will not deform due to heat, and the platform temperature is kept constant. The ultimate 4pl printhead technology delivers high-resolution printing quality that rivals photo quality. Professional production and assembly processes ensure perfect machine quality. It adopts high-quality components such as German EGUS drag chains, Japanese Panasonic servo motors, and Italian Megadyne synchronous belts. The steel beam and dual rail structure ensure stable system operation. The movement of the printhead carriage is guided by a fixed linear encoder to ensure high-precision printing positioning. The fastest fiber optic data transmission technology with a speed of 1.25Gb/s ensures zero interference. It uses an industrial-grade PCI data transmission interface with strong anti-interference capability. The negative pressure air source protection is activated in case of power failure. It has an automatic media collision prevention system to avoid damage to the printhead caused by collisions. The machine has self-detection of operational faults. It features a precise printhead temperature control system with dual heating. It is designed to meet the requirements of 7 days x 24 hours of production. The software has a user-friendly dialogue interface for easy operation.